Xa i-cylinder eqhelekileyo isebenza, ngenxa yokunyanzeliswa kwegesi, xa umthwalo wangaphandle uguquka kakhulu, into eyenzekayo "yokukhasa" okanye "i-self-propelled" iya kwenzeka, eya kwenza umsebenzi we-cylinder ungazinzi.Ukuze wenze isilinda sihambe kakuhle, i-cylinder yokudambisa ulwelo lwegesi ingasetyenziswa ngokubanzi.

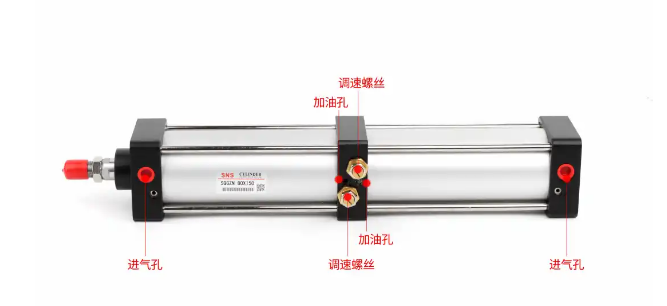

Isilinda sokudambisa ulwelo lwerhasi ikwabizwa ngokuba sisilinda esinesantya esizinzileyo segesi.Yenziwe nge-cylinder kunye ne-oyile cylinder.Isebenzisa umoya oxinzelelweyo njengomthombo wamandla, kwaye isebenzisa ukunyanzeliswa kweoli kunye nokulawulwa kwe-oil displacement ukufumana ukuhamba kakuhle kwepiston.Lungisa isantya sokuhamba kwepiston.

Idibanisa i-cylinder yeoli kunye ne-cylinder kwi-series ibe yinto yonke, kwaye iipiston ezimbini zigxininiswe kwintonga ye-piston. ekhohlo ngaxeshanye.Ngeli xesha, i-cavity ekhohlo ye-cylinder ikhupha ioli kunye ne-valve yendlela enye ivaliwe.Ioyile iqukuqela kancinane kwicango lasekunene lesilinda ngevalve ye-throttle, ithomalalisa intshukumo yepiston yonke..

Injongo yokulungelelanisa isantya sepiston inokufezekiswa ngokulungelelanisa ubungakanani be-valve port of valve throttle valve.Xa umoya ocinezelekileyo ungena kwicango lasekhohlo le-cylinder ngevalve ebuyela umva, umgodi osekunene we-cylinder ukhupha ioyile.Ngeli xesha, i-valve yendlela enye ivuliwe, kwaye i-piston inokubuyisela ngokukhawuleza kwindawo yayo yokuqala.

Iimbonakalo:

I-cylinder ye-gas-liquid damping cylinder isebenzisa i-gas ukutyhala ioli ye-hydraulic ukwenza i-cylinder ihambe ngokulinganayo kwaye ihambe kakuhle ngaphandle kokugubha.Olu hlobo lwemveliso lunokulawula isantya sangaphambili nasemva kwe-cylinder ngokusebenzisa iivalve ezimbini zokulawula kwikhava ephakathi.Ukongezwa kuyacotha, ukurhoxiswa kuyakhawuleza, okanye ukongezwa kuyakhawuleza, kwaye ukurhoxiswa kucotha, kwaye kulula ukuyisebenzisa.

Isicelo:

Iisilinda zokudambisa ulwelo lomoya zisetyenziswa ikakhulu kwizixhobo zokutya rhoqo kwizixhobo zoomatshini kunye nokusika oomatshini.Umzekelo: ukuprinta (ulawulo loxinzelelo), i-semiconductor (umatshini we-spot welding, i-chip grinding), ulawulo oluzenzekelayo, iirobhothi kunye nezinye iinkalo.

Ixesha lokuposa: Jul-02-2021